BMT65: Significant increase in performance and service life

Products |

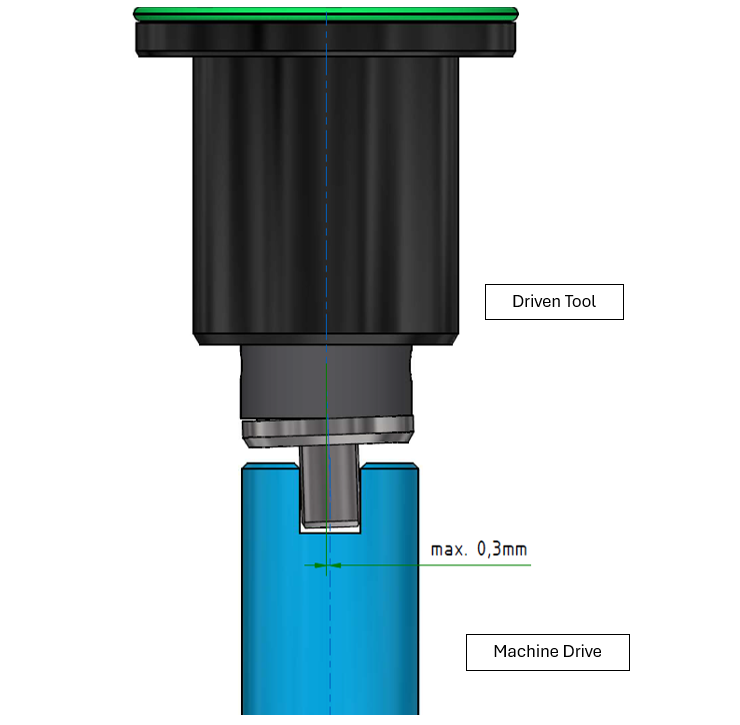

Flexible coupling in detail

The new coupling compensates for misalignment with a maximum radial offset of 0.3 mm between the driven tool and the machine drive. The coupling joint swivels in one axis and slides into the groove of the drive in the second plane, similar to the Oldham principle. In addition, an elastomer support ring reduces vibrations and noise.

Progress through new coupling technology

- Compensation of misalignments up to max. 0.3 mm

- Reduction of bending moments in the driven tool and increase in bearing service life

- Reduction of wear on the double flat

- Reduction of vibrations and noise

EWS.Techline in harmony with the new coupling

EWS.Techline is characterized by four groundbreaking innovations. The EWS.HPC-Line revolutionizes performance with its ceramic seal at up to 12,000 rpm and 70 bar unrestricted dry running. EWS.Polygon-Joint redefines the limits of torque transmission and enables an increase in performance of up to 30 percent with increased impact and breakage resistance, while EWS.Butterfly-Seal offers maximum protection against direct contact with cooling emulsion and dirt particles. EWS.Coolant Management completes the overall package with its universal coolant management, which can open and close the external cooling system with a single turn.

Wide selection for your metalworking needs

The new coupling and holder generation is already integrated in all driven tool systems with BMT65 in the Tool-Finder. Around 25 manufacturers and 130 machines are available to choose from, so that the right tool system can be found for every application.

Discover the right BMT65 tool holder for your application now!

The most important links at a glance:

EWS Newsletter: The most important news conveniently in your mailbox