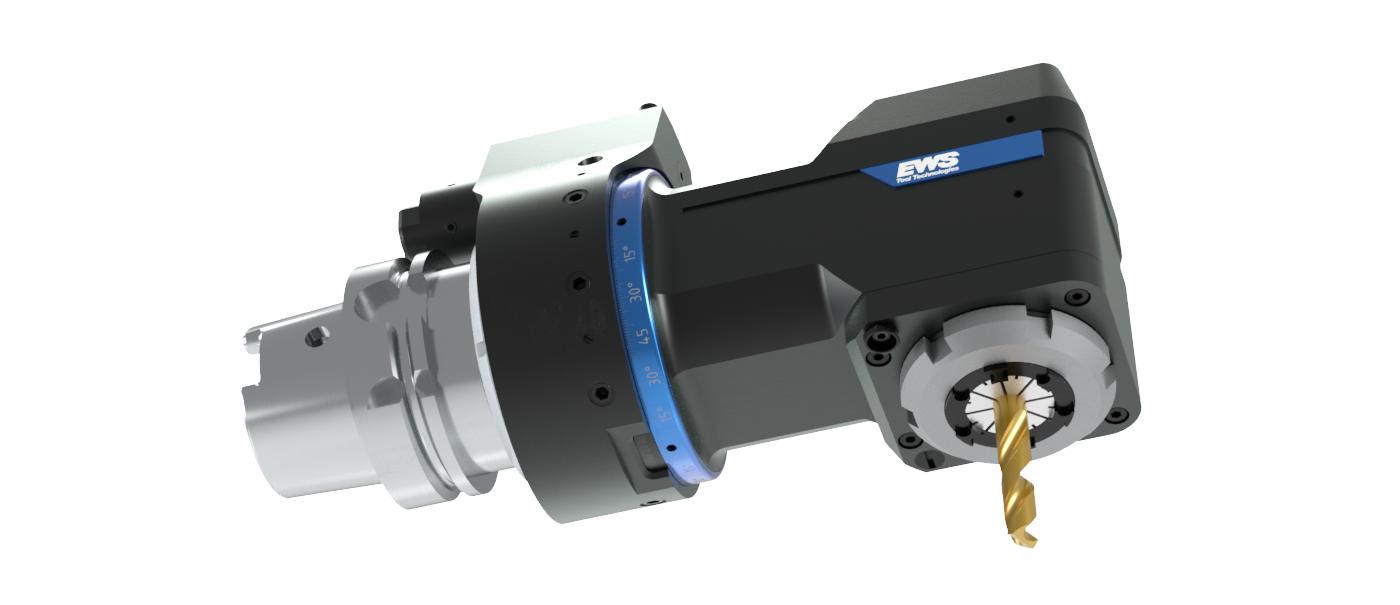

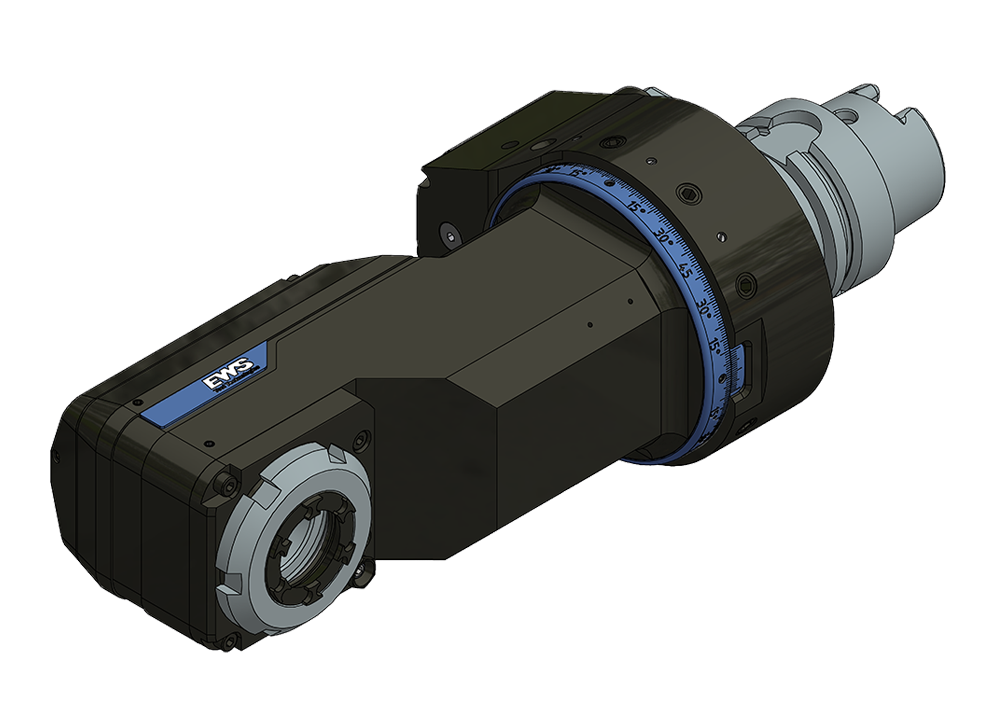

The new EWS.millLine range brings proven technology with new features to the machining centers.

EWS.millLine - Angle heads for machining centers

EWS goes milling

With the new angle head program, EWS brings proven technology with new features to the machining centers. Elegant design encloses high-performance technology, or simply precision meets motion.

Advantages

- The smart solution to compensate for a missing machining axis

- Machining workpieces that are difficult to access

- Internal bore machining

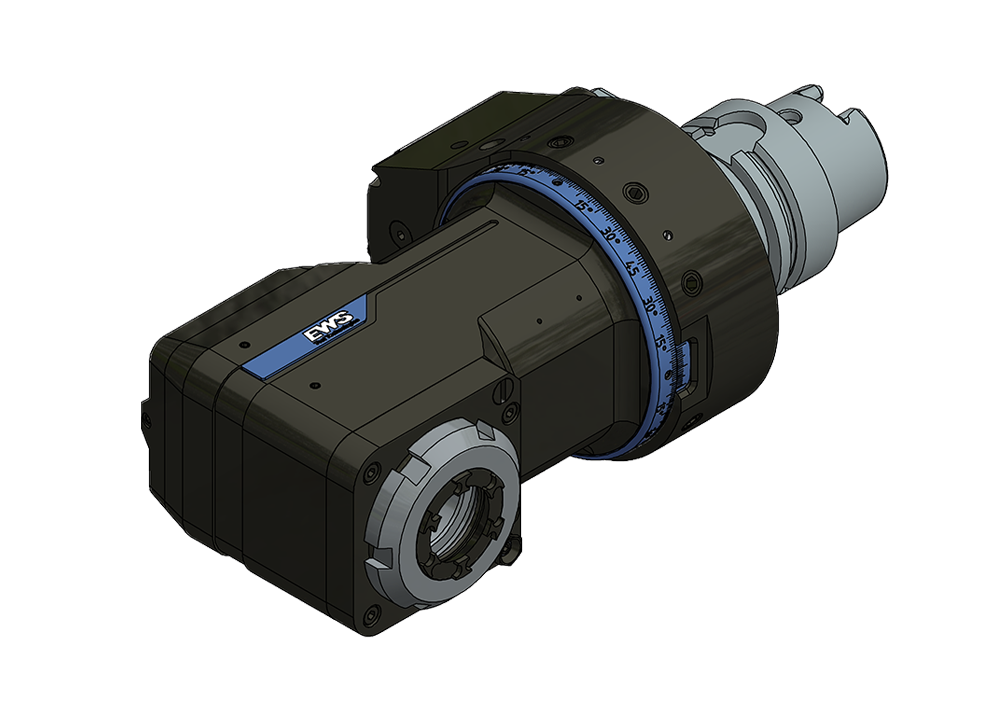

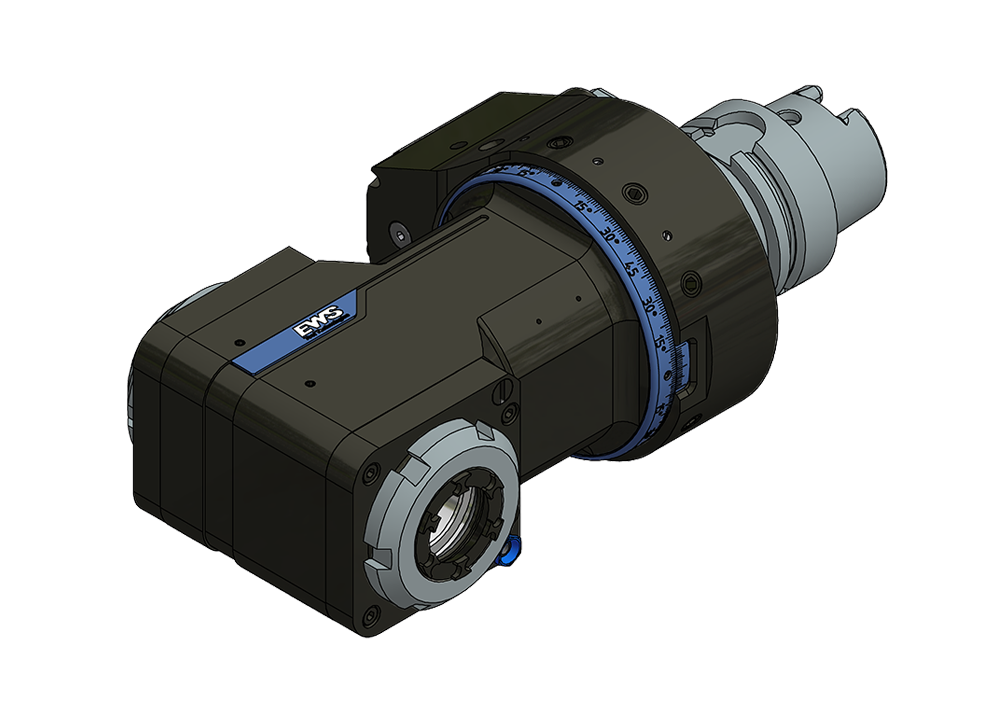

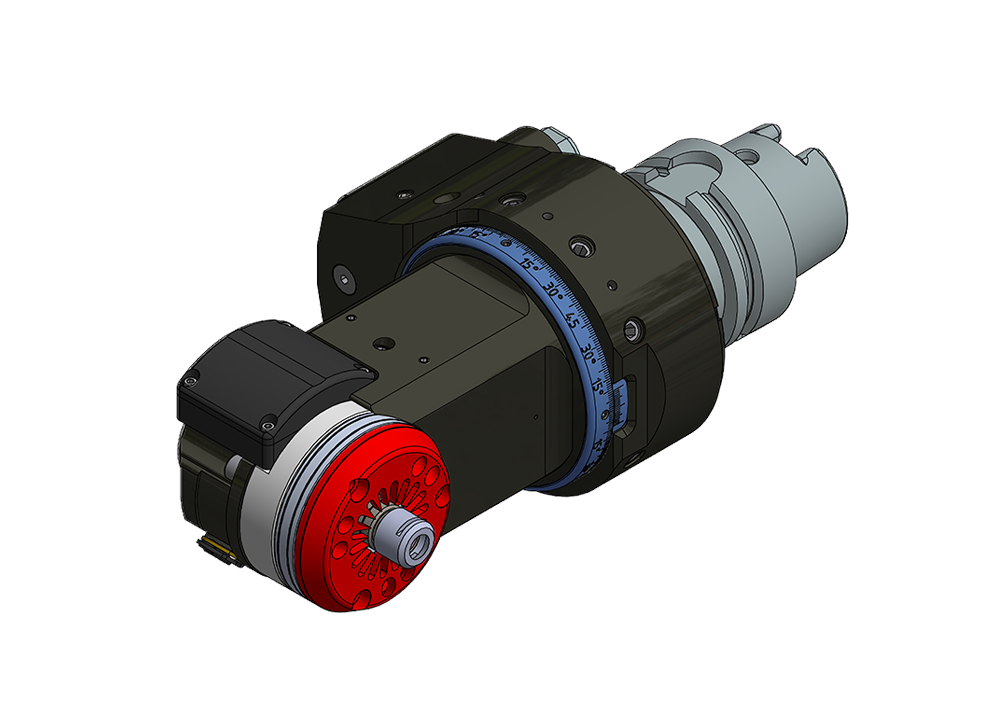

- Stepless angle adjustment

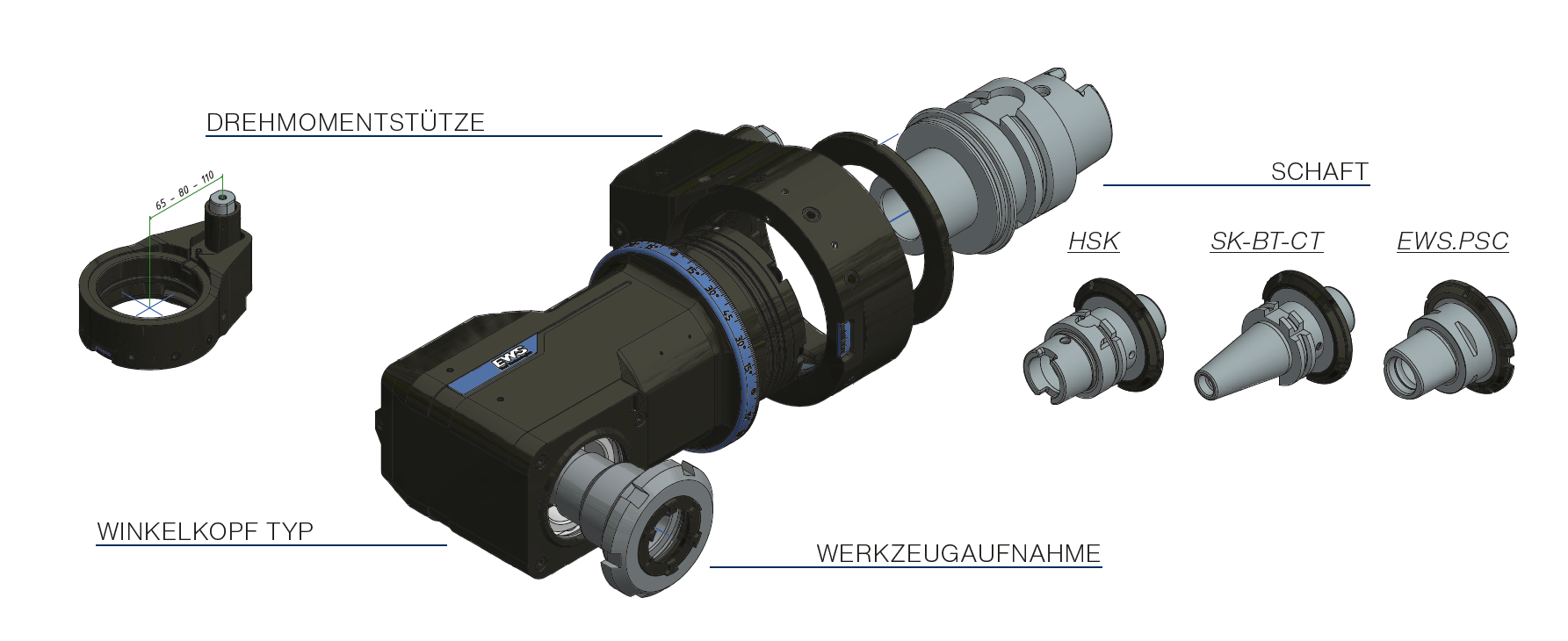

Modular design Angle heads

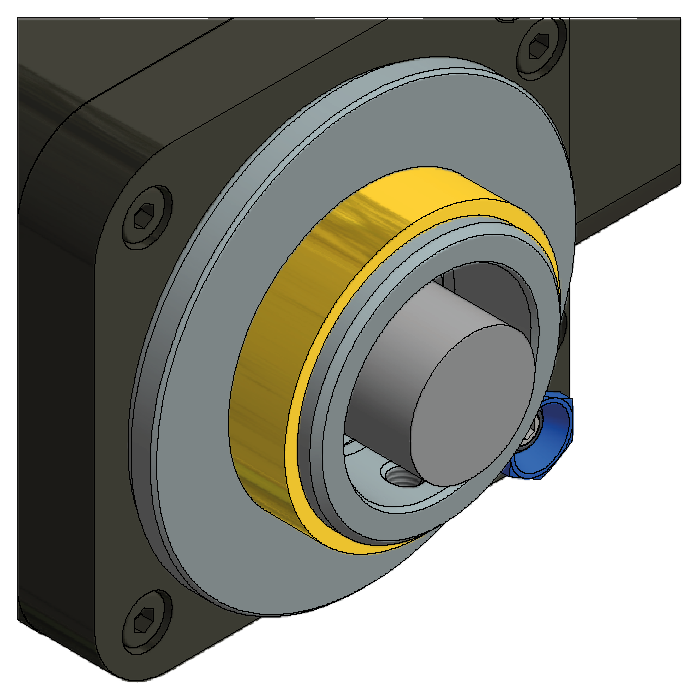

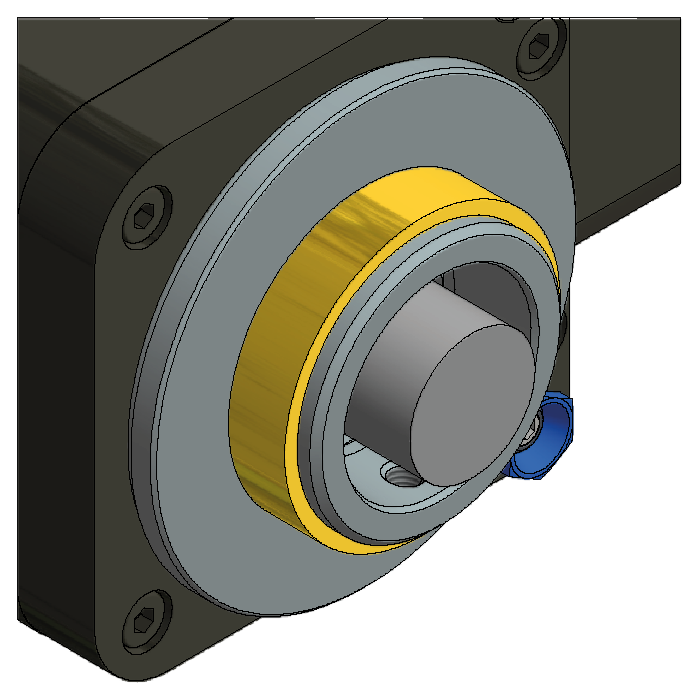

The modular design of the angle heads enables numerous combinations of shank, angle head type and tool holder.

Angled head variants

EWS offers a variety of differently configurable angle heads, whether Basic with 90° tool holder, Duplex with 90° tool holder on both sides, the Offset variant with 90° recessed tool holder or as a tool holder with freely adjustable angle.

BASIC

Angled head 90° tool holder

Optionally with external cooling

DUPLEX

Angled head 90° tool holder on both sides

Optionally with external cooling

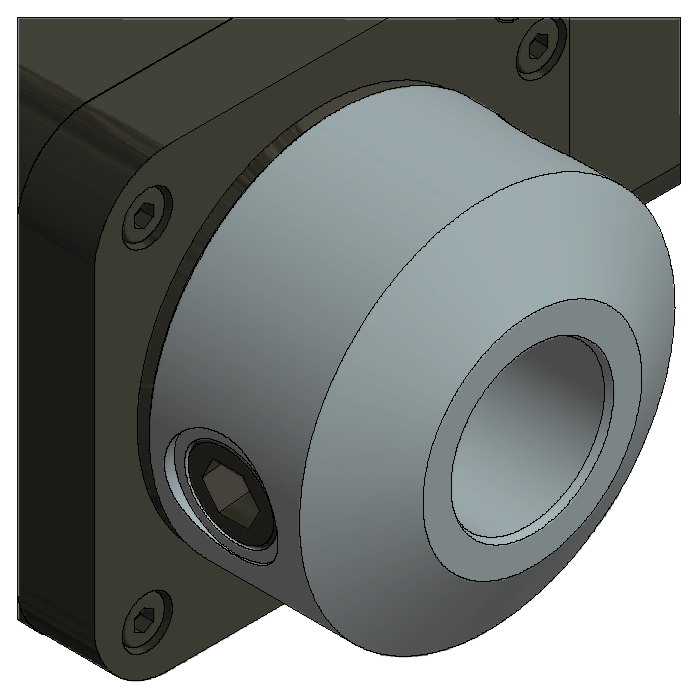

OFFSET

Angled head 90° recessed tool holder

Optionally with external cooling / internal cooling

SWIVEL

Angle head 0-92° infinitely adjustable

SPINJET

Angle head 90° driven via coolant pressure

Types of tool holders

ER-Collet

Varia VX

HSK

KM

Weldon Whistle Notch

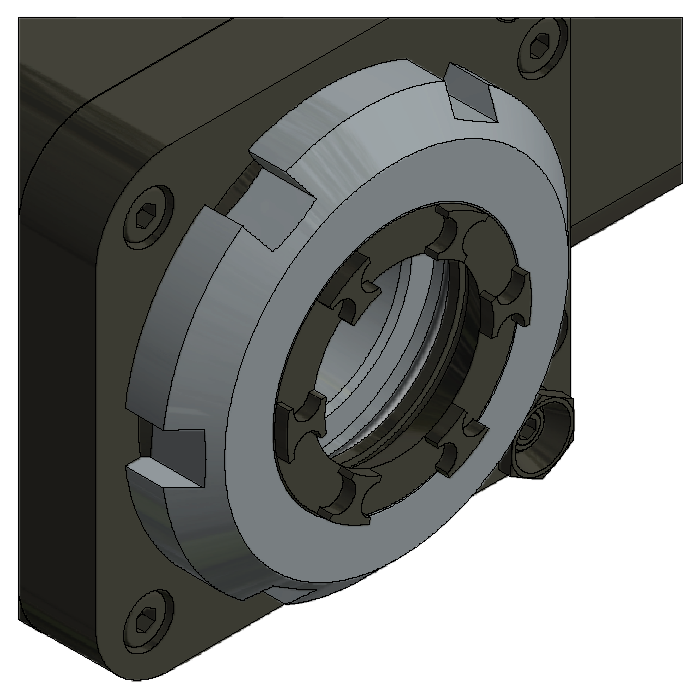

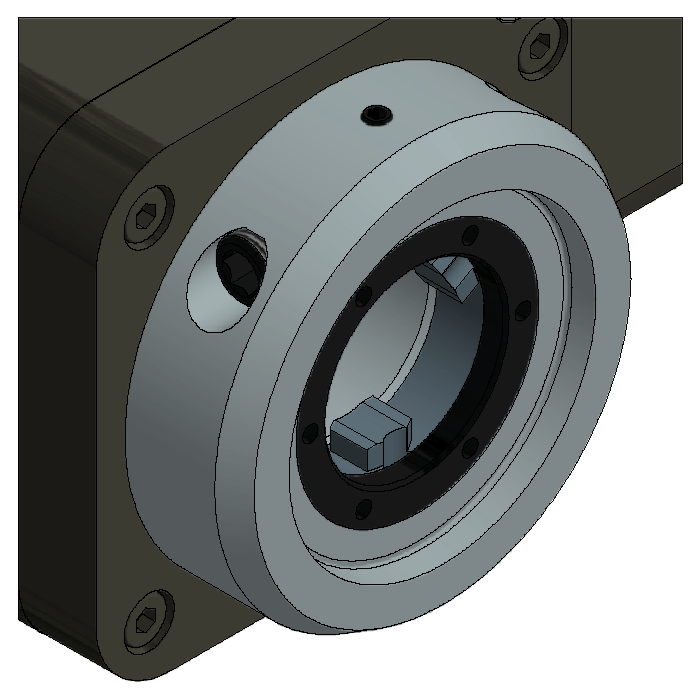

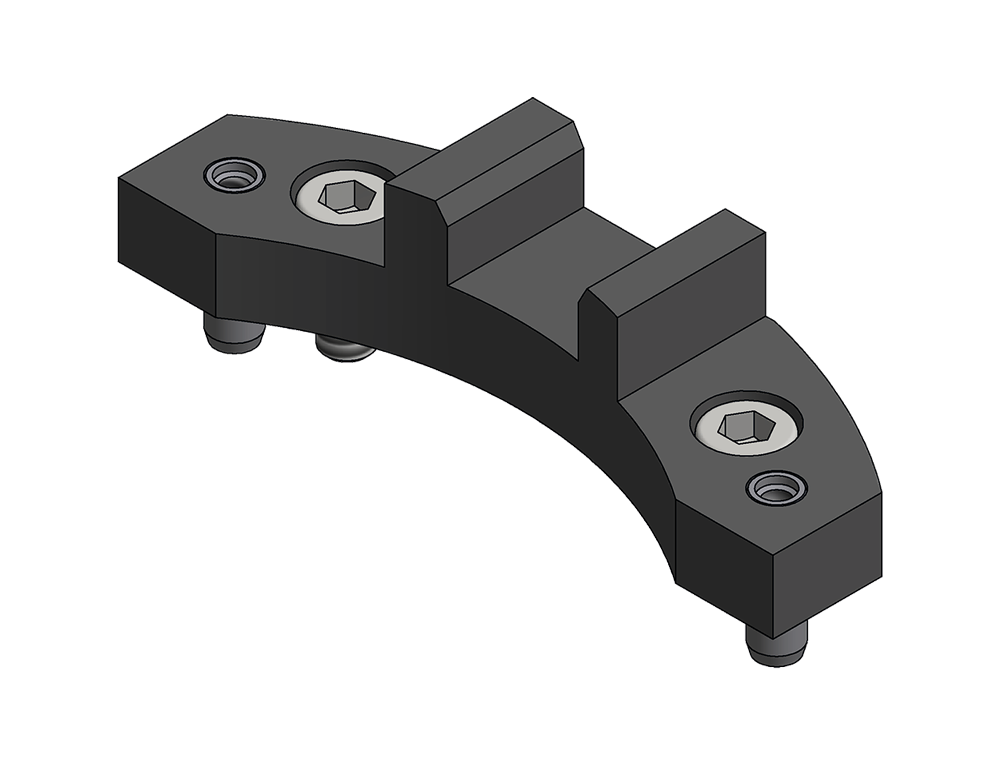

Prerequisite

The basic requirement is a "stop block" on the machine, which prevents the entire unit from rotating and at the same time defines the twisting position.

Further information on EWS.millLine as a download