Grooving in a new dimension

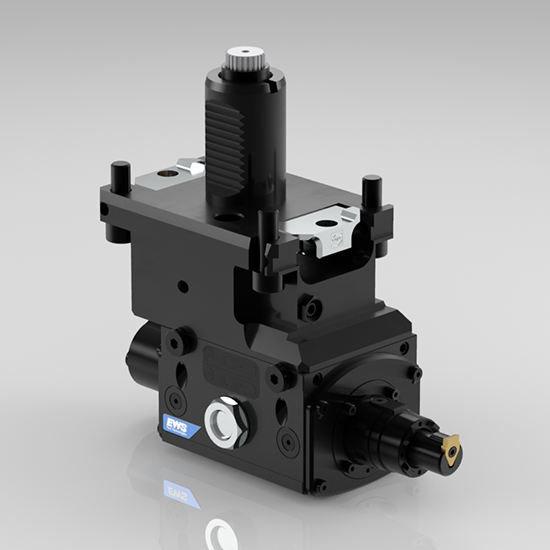

EWS.Slot - Slotting, Internal and External Toothing

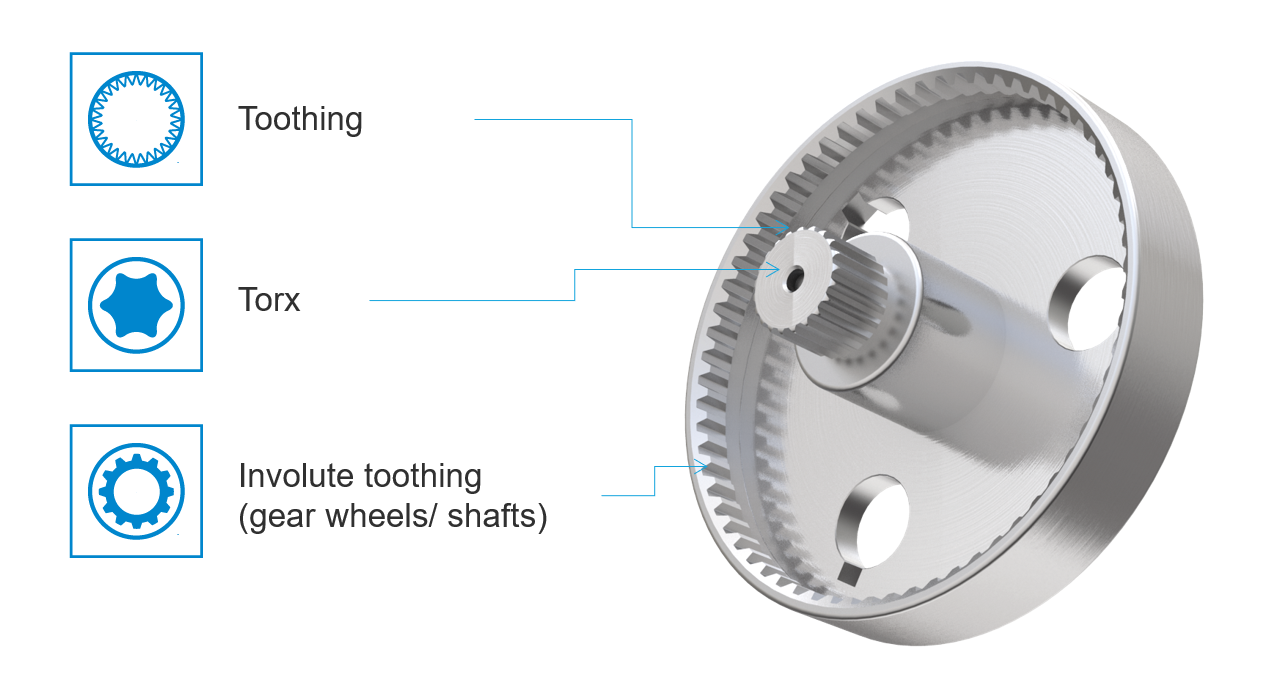

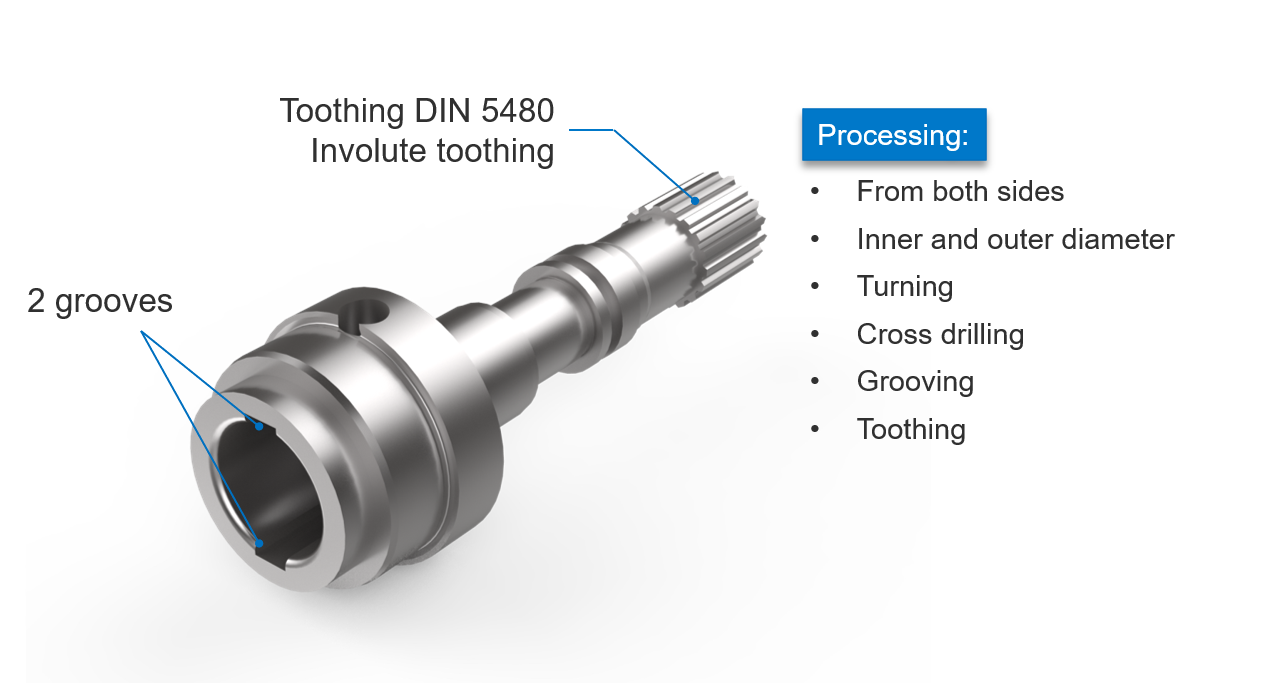

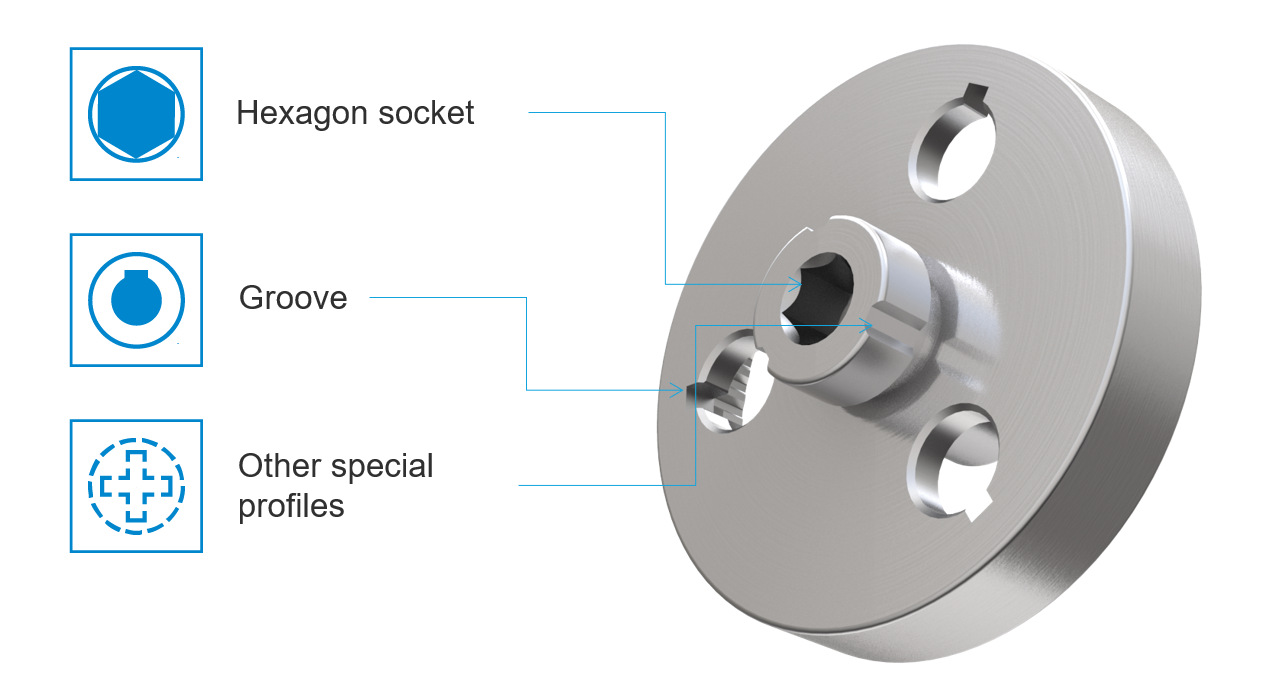

Slotting, internal and external splines manufactured completely and position-oriented

The EWS-Slot grooving unit is driven by the machine's tool turret, converting the rotary motion introduced into translation with a superimposed lift-off function. This makes programming extremely simple. The grooving unit is positioned in the prepared hole in such a way that the extended ram is at the end position in the Z axis. The groove depth is realized by a constant X feed, which varies between 0.04-0.15mm/stroke depending on the version.

The spindle speed ranges between 400 rpm - 1,200 rpm, with one revolution corresponding to one complete stroke. Thus, for example, a keyway with a width of 6mm and a depth of 5mm is produced within 7.5 sec. (800 rpm and 0.05mm feed/rotation) It is important in this operation that the chip can break at the end of the slot, i.e. that there is a recess or hole. But not only grooves, internal and external splines are also possible. This is particularly interesting for workpieces with partial splines.

Function

- The newly developed EWS-Slot grooving unit converts the rotary motion of the turret drive into a translatory motion with integrated lift-off function during the return stroke.

- The economical production of internal and external profiles, such as keyways or splines, takes on a new dimension.

- Grooving units can be operated at up to 1500 1/min.

Processing examples