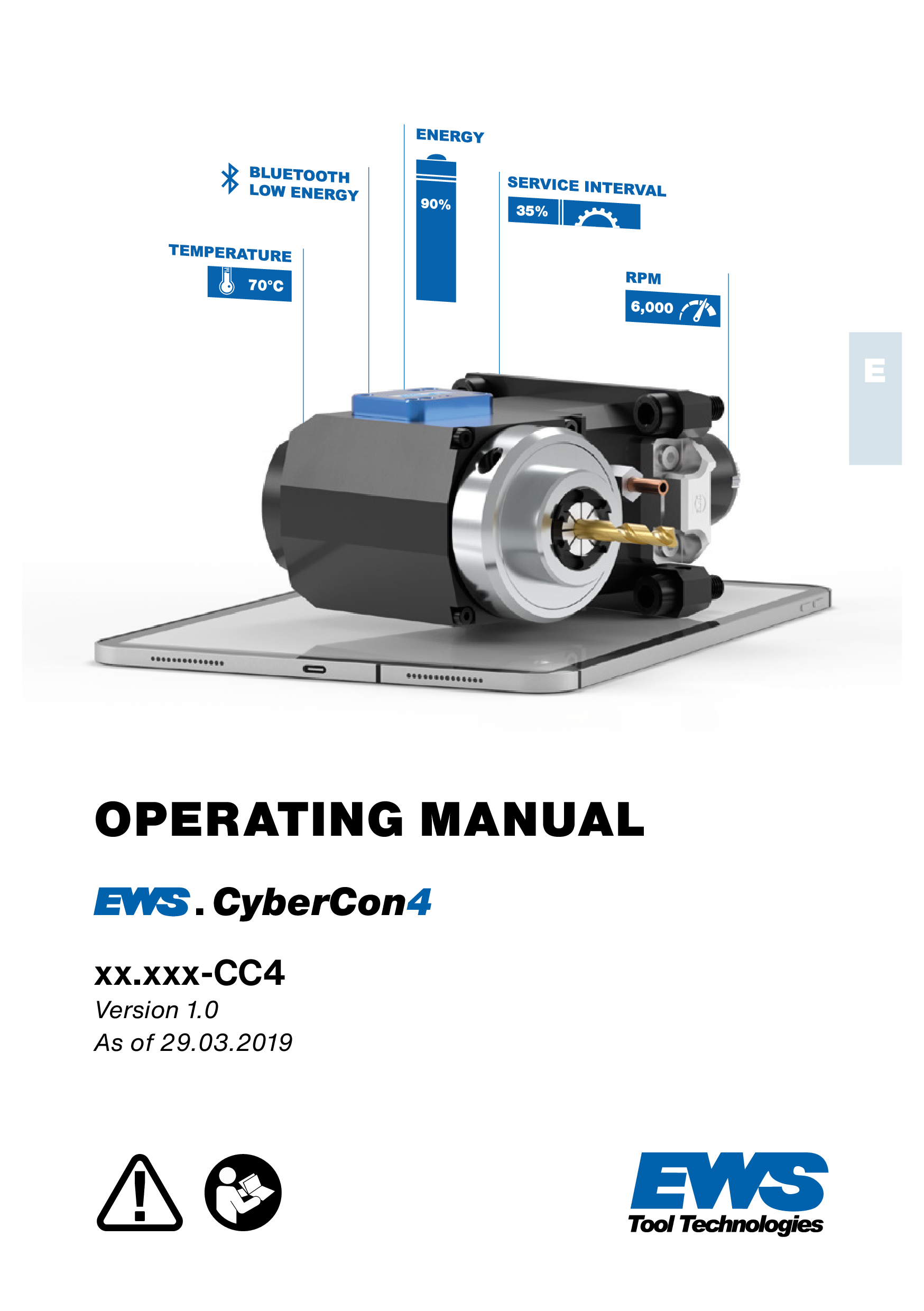

CyberCon4 from EWS provides the user with a digital insight into the kinematic processes of their tool. A tool holder equipped with CyberCon4 collects comprehensive data for checking and monitoring the tool used. This data collection facilitates both the prevention of damage to the machine and the collection of data for store floor management.

EWS.CyberCon4 - Sensor technology for driven tools

The digital view for capturing cinematic sequences

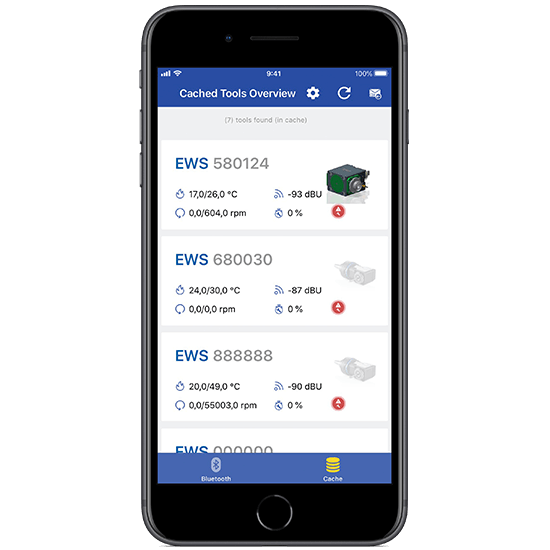

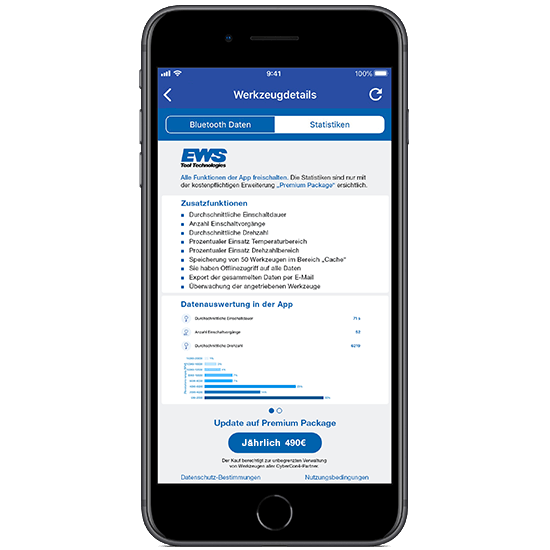

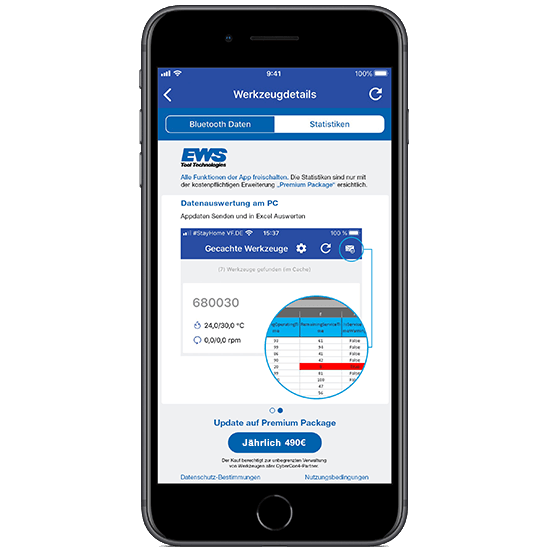

EWS develops its own sensor technology as part of the Industry 4.0 concept. With EWS.CyberCon4, EWS is entering the age of digital transformation. The digital concept is also open to cooperation partners in order to offer users as much standard as possible. The data can be read on a tablet or smartphone via an app. However, this is only part of the possibilities. EWS.CyberCon4 is a building block of the overall IoT concept from EWS. In addition to the sensor system, new technology features such as the new "HPC-Line" sealing concept are used. Initially, the sensor system is only available in Germany and Austria.

Optimization of cutting-edge technology

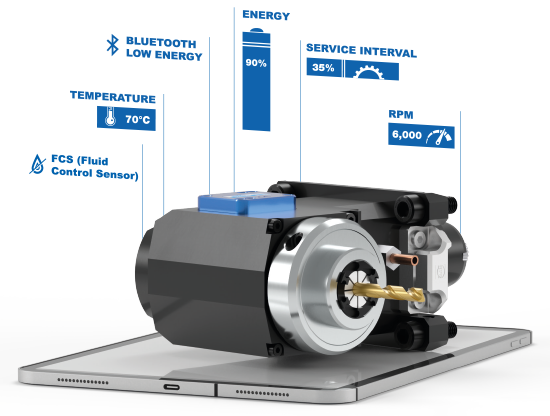

Futuristic, based on BLE with advertising packages sent at intervals of a few seconds.

Functions | |

Temperature: Current and max. | Number of switch-on operations |

Speed: Current and max. | Average speed |

Remaining term until service in % | Speed range during use |

Battery status | Temperature ranges during use |

Data export options for further processing | Evaluation for an unlimited number of tools |

→ Available free of charge in the App Store / Google Pay |

The advantages

- Avoid costly machine downtimes thanks to intelligent tool system

- Dynamic determination of load-dependent maintenance cycles

- Sensor technology is open for communication with external interfaces

- Data management, internal and external

- Sensor is based on BLE 4.1 technology (Bluetooth Low Energy)

- Detection of seal failure by "FCS (Fluid Control Sensor)" before machine damage occurs

Discover the app now!

Click on the logos below to download the app.

Closing gaps in data collection

The factors that can be measured with CyberCon4 all serve an important purpose and are therefore almost indispensable for production with low downtimes. Controlled monitoring of the tools used helps to identify sources of error and avoid them in the future.

How the sensor works

In its initial situation, the sensor is basically in stand-by mode. This creates the advantage of increased battery life. In order for the sensor to start working and thus measure and transmit data, it must first wake up from stand-by mode. This happens as soon as the tool starts to rotate. The sensor detects the rotations of the tool by means of a small magnet incorporated in the tool spindle. The exact number of rotations can be recorded by means of the magnetic field that passes the sensor with each rotation.