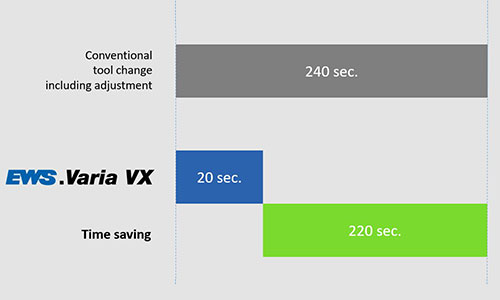

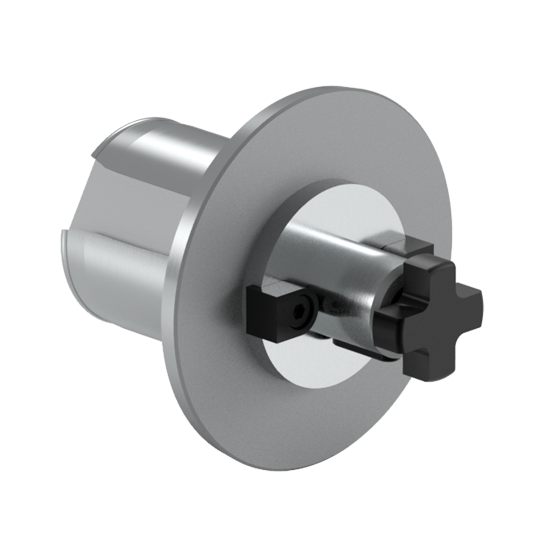

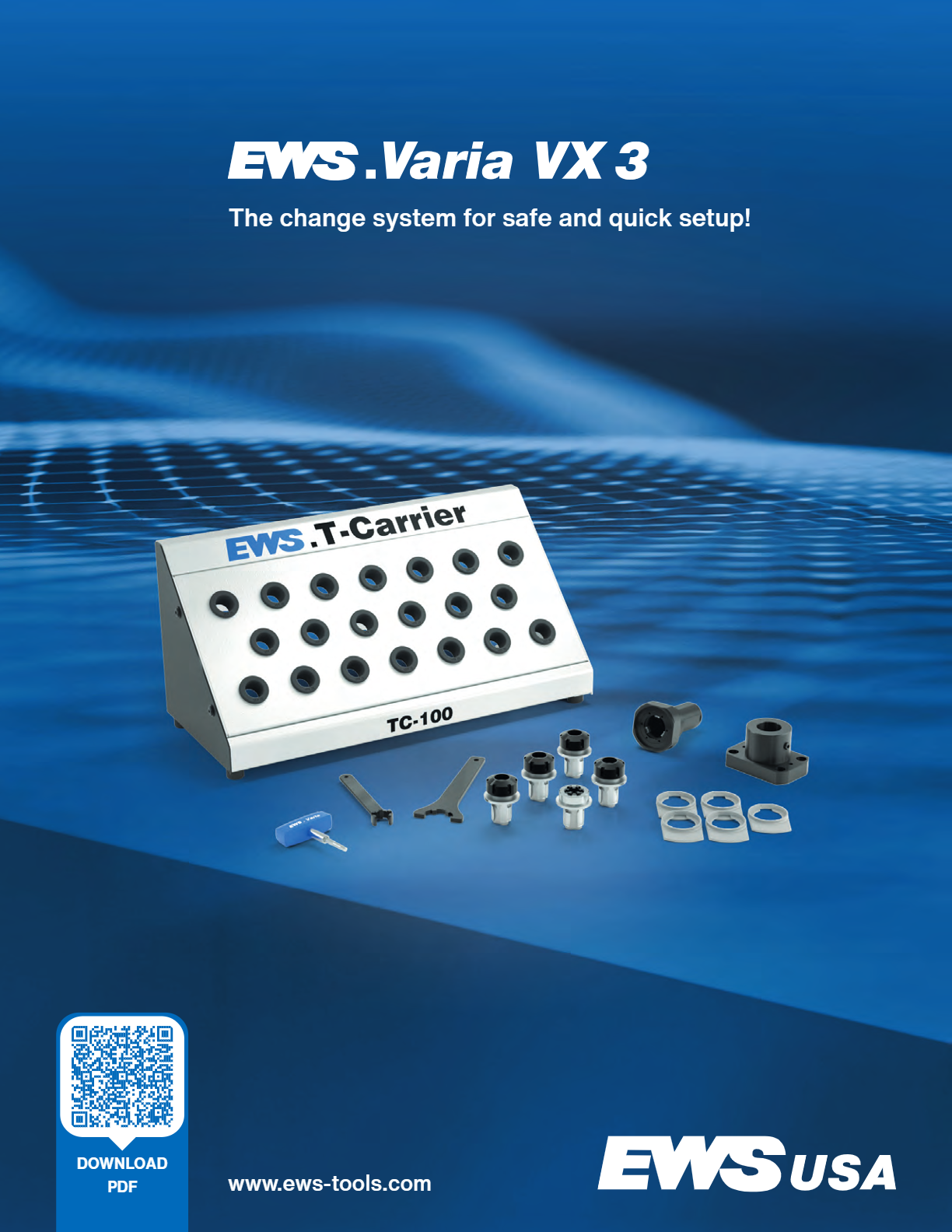

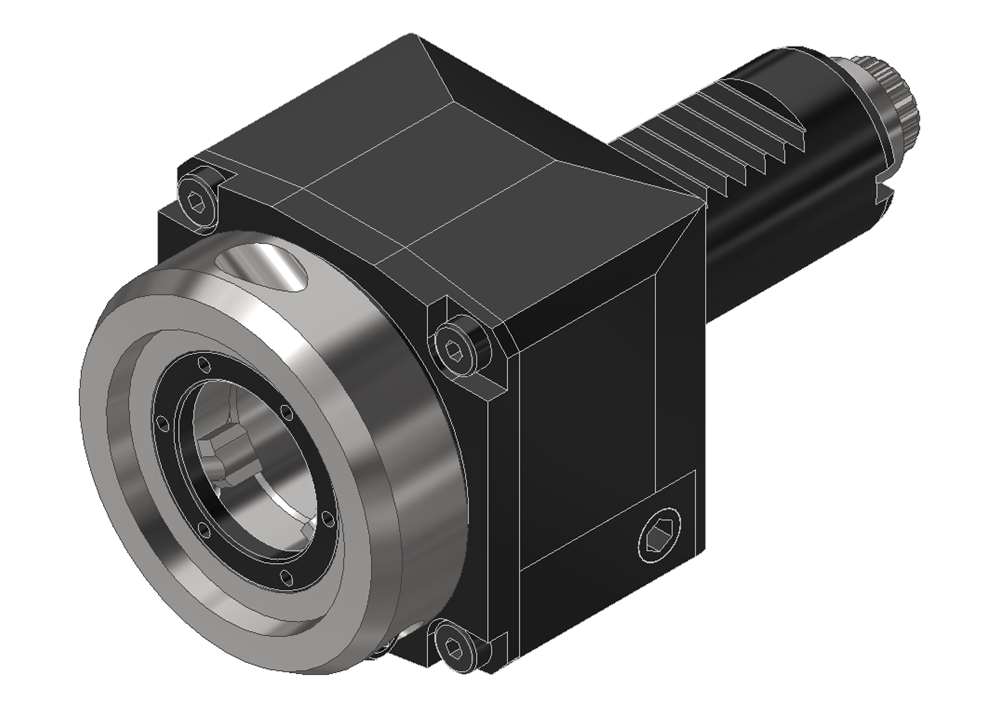

With the patented EWS.Varia VX quick-change system, you perform tool changes faster than your competitors.

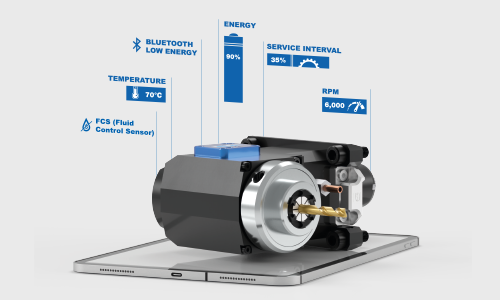

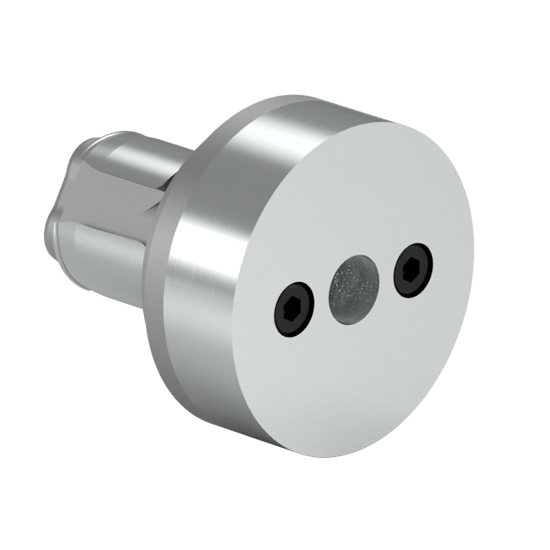

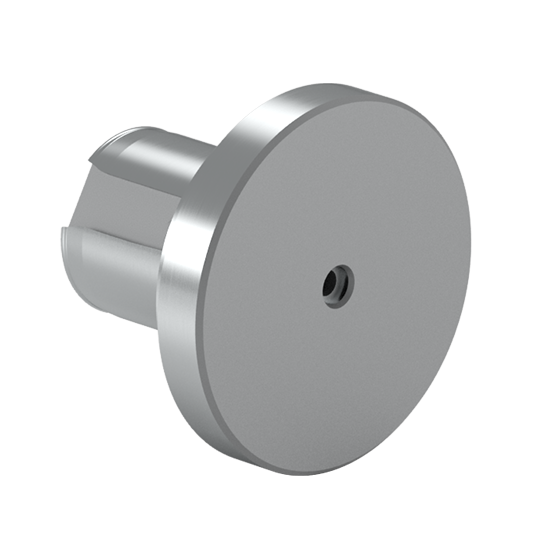

In addition, your driven tool will adapt to your requirements in the future.

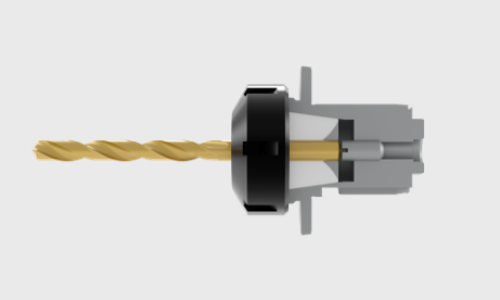

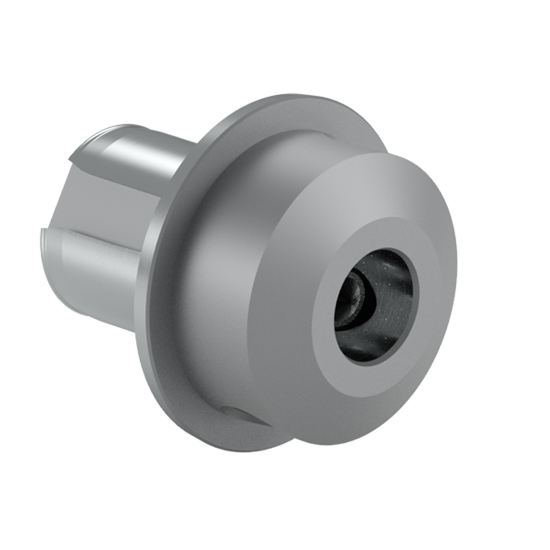

The modular interface allows you to select the ideal tool clamping for every machining process.

.png)