More than just a groove: when manufacturing becomes a strategy

Products |

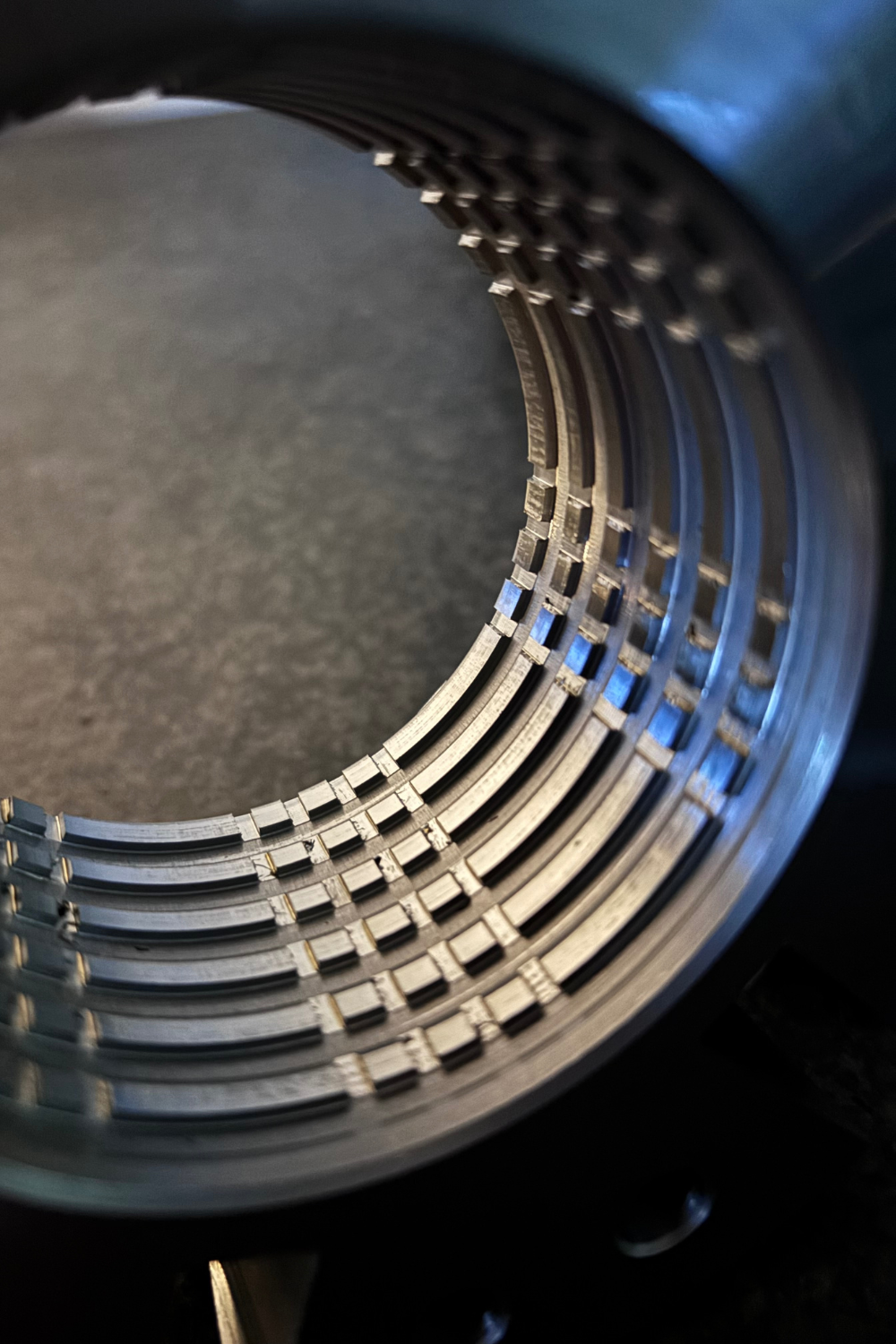

Inner contour butted

Often reduced to classic feather key grooves, it is actually a highly precise, versatile machining process, especially if you think about it from the outset. This is precisely where the connection between Joachim Heuer, Managing Director of Heuer Präzisionsteile GmbH and founder of Heuer Radsport, and Matthias Weigele, CEO of tool manufacturer EWS Tool-Technologie, comes in.

Their collaboration did not arise from a glance at the catalog, but from real challenges in manufacturing issues and a shared desire not only to apply technologies, but to think them further.

After all, the use of technology begins much earlier: in development. Anyone who designs components without knowing the latest manufacturing technologies is not limited by the machines, but rather by their own horizons. Or as Joachim Heuer puts it from an application perspective: "You can only ask what you can imagine - and you can only imagine what you have already seen. "

Recognizing potential - and exploiting it right from the start

Many technicians immediately think of the classic keyway when they think of shaping, but this is only the simplest or even best-known application. Another example of an application is the production of an internal hexagon: "When a customer from the design department recently said: "That's complex - free drilling the corners, circular milling 30 mm in depth, you can hardly get in that deep", I had to smile. The component had long since been shaped in my mind - but this option didn't even exist in his head yet, " says Heuer.

Today, a contour during shaping is often only limited by how a shaping tool can be ground - and this applies to both the internal and external geometry. Matthias Weigele adds: "The process is suitable for any shape that has a groove character, and the geometry limits are not defined by the machine, but by the tool kinematics and the structure of the cutting edge." This opens up scope for complex, economical machining operations that would often be costly or impossible to achieve with other processes.

Challenges in development

In practice, there is no "ideal geometry". There are only geometries that can be produced better or worse under certain conditions. Anyone who integrates technologies such as shaping into their way of thinking shifts this boundary decisively, especially in the case of complex or recurring contours . "If I know that I can also shaping deep internal contours with sharp corners cleanly, then I design completely differently," explains Joachim Heuer . "Suddenly, a seemingly difficult component becomes a task that can be solved perfectly and economically. "

Recurring patterns, such as internal corners for square or hexagonal gears, splines and other positive-locking profiles, can be produced particularly efficiently with the shaping technology. Special shapes, where specific corners need to be cut out or defined radii produced - for example for position or sensor rings - can also be machined directly in a single clamping operation. This becomes economical with tools that have a contour machined multiple times. Instead of shaping 60 teeth individually, for example, a cutting insert can be produced for three tooth segments. The result: a third of the machining time. Design and costs are therefore directly related - those who design components with process understanding already decide on efficiency, runtime and cost-effectiveness in the design phase. The challenge therefore lies not only in the machinery, but in the approach.

Practical example: Using groove joint technology correctly

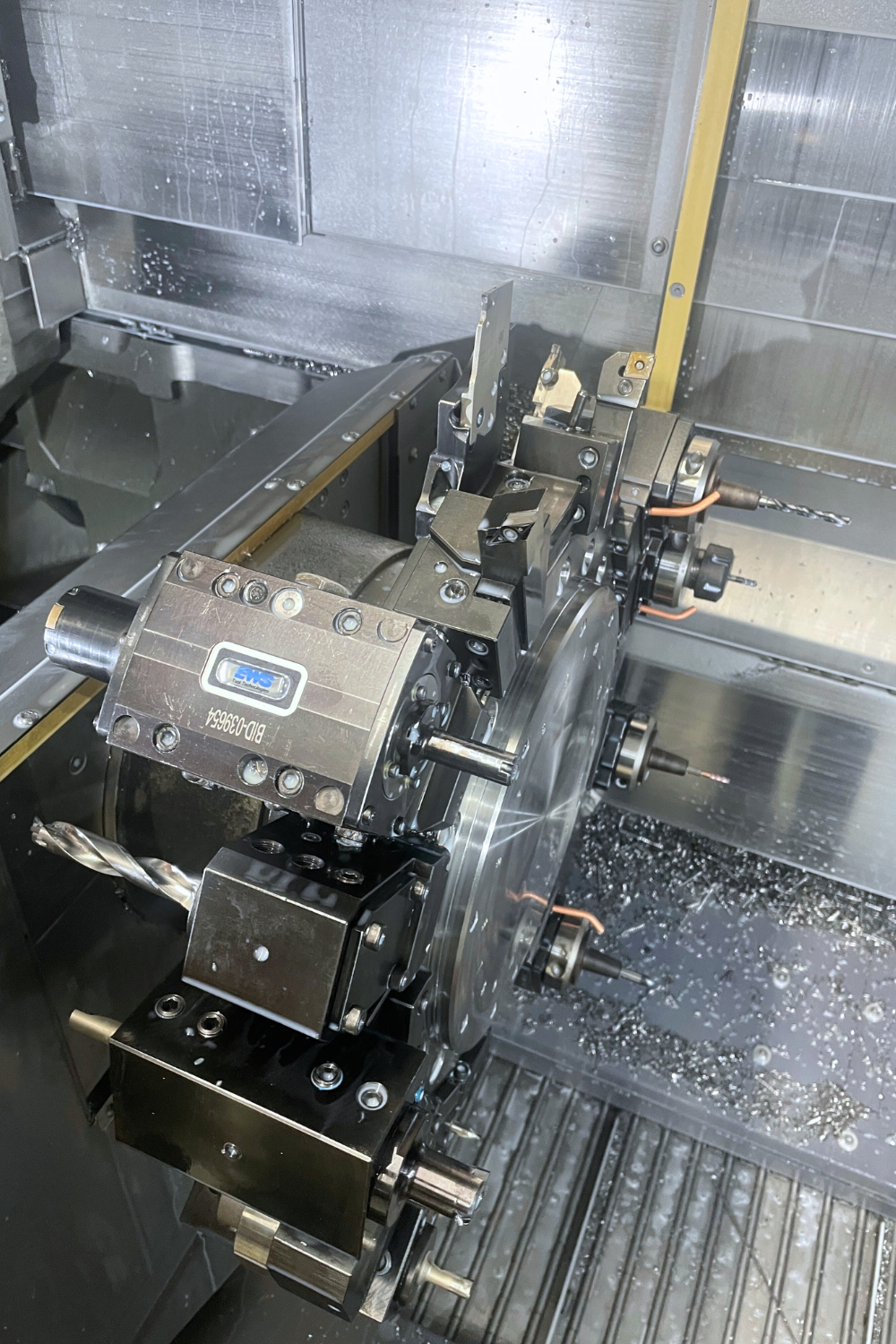

In der Fertigung von High-Performance-Radsport Komponenten setzt Joachim Heuer die Stoßtechnologie gezielt dort ein, wo konventionelle Verfahren an ihre Grenzen stoßen – oder schlicht zu aufwendig wären. Heuer integriert sie direkt in die Prozesskette – inline, automatisiert und ist zudem verschleißarm. Betrachtet man beispielsweise eine seiner Ritzelaufnahmen des Freilaufkörpers, wirkt diese mit mehreren Nuten am Außendurchmesser auf den ersten Blick unspektakulär. Doch genau diese Nuten entscheiden darüber, ob das Bauteil spielfrei greift und Kräfte optimal überträgt. „Es handelt sich hierbei also um funktional anspruchsvolle Geometrien, die mit der richtigen Technologie wirtschaftlich sauber lösbar sind", so Heuer. „Früher haben wir mit einem kleinen Werkzeug Bahn für Bahn gefräst, bei deutlich hoher Bearbeitungszeit. Später haben wir die Teile mit der Z-Achse gestoßen, was eine hohe Maschinenbelastung und einen großen Werkzeugverschleiß zur Folge hatte. Mit dem Stoßapparat von

The difference can be seen in the details:

- No punctual load on the ball screw, as the dynamic movement takes place in the unit.

- The set speed enables us to achieve high cutting speeds and therefore shorter machining times and reduced tool wear.

- High repeat accuracy, even with complex internal contours, as there is no reclamping.

The result: Components are produced that are not only functional, but also economical to the point - with short cycle times and high process reliability.

Rethinking the joint: applications beyond the groove

Matthias Weigele also believes that shaping has long been more than just traditional grooving . "The term 'grooving unit' is actually too short-sighted," says the CEO of EWS Tool-Technologie . "Although the unit was originally designed for grooving, our customers now use it for a much wider range of tasks. "

Another example is a control ring with complex segment toothing on the outer diameter. The toothing is cut in clockwise rotation of the turret drive - precisely, positively and in just a few seconds. In the same clamping process, a control cam with a sharp-edged geometry is cut on the inner diameter in a second machining step. This is made possible by a special cutting edge that eliminates the radius that is usually required for production. This double machining - outer in X-, inner in X+ - shows how versatile the unit can be. The underlying kinematics are always the same: a defined rectangular movement with forward, lift-off, backward and infeed phases.

"The unit performs the dynamic movement completely independently," explains Weigele. "The machine control system only sets the feed rate - the stroke length is constant and the impact depth is positioned via the Z-axis. " For the machining process to work, there must be a clearance hole or undercut at the end of each operation - so the chip can be broken safely. EWS offers the unit in two standard versions: with 32 mm and 51 mm effective length - tailored to the most common applications in toolmaking and mechanical engineering.

Why technological expertise brings competitive advantages

What Joachim Heuer and Matthias Weigele have in common is a conviction: technology should not be used reactively, but should be actively considered in order to gain a real competitive advantage. The design stage is where a company decides which manufacturing options it will or will not use. Those who only think in terms of geometries are thinking too short-sightedly. Those who incorporate technology from the outset develop components that not only work, but can also be produced economically, efficiently and reliably. For Joachim Heuer, this has long been part of everyday life - both at Heuer Präzisionsteile and at Heuer Radsport: "Our technical expertise is not just a means of production - it is the basis of our development. This creates solutions that others only come up with at the third attempt." For Matthias Weigele, it is clear: "If we think machines, tools and applications together today, then solutions are created that not only work well, but are better in the long term ."

Their appeal to the industry: designers, developers and manufacturers must learn to think together. Not everyone needs everything - but everyone should know what is possible. Because real innovation does not start with a tool - it starts with an idea that is open to technology. Those who know tools can design processes. Those who can design processes design differently. And those who design differently open up new possibilities - both technically and economically. And it is precisely this change of perspective that makes the difference.

About Heuer Präzisionsteile and Heuer Radsport

Heuer Präzisionsteile GmbH stands for precise CNC machining of complex components, specializing in small to medium series, tight tolerances and sophisticated geometries. Production takes place in southern Germany, primarily for mechanical engineering, medical technology and special vehicle construction.

With Heuer Radsport, Joachim Heuer bundles the development, design and production of its own high-end components for cycling - including freewheel bodies, hubs and wheels. The focus is on system solutions with a technological edge.

Both brands are united by a clear claim: technology is not only used, but also thought through - functionally, constructively and with an eye for the essentials. www.h-pt.de

The most important links at a glance:

EWS Newsletter: The most important news conveniently in your mailbox