Industry around the world is under increasing pressure. Global economic policy, a growing shortage of skilled workers, rising energy and raw material costs combined with growing demands on production speed, quality and variant diversity are key pain points across all industries. Process optimization is a central element of any strategy dedicated to overcoming these challenges. The aim is to continuously optimize processes and tools in order to produce the same or even larger quantities with the same high quality, in less time and using fewer resources.

EWS.Varia VXT: Competitiveness through innovation

Products |

Set-up times are the bottleneck of machining technology

Industrial machining technology is also confronted with the aforementioned challenges. In addition to various aspects of process optimization, tool changing on cutting machines is a particularly sensitive work step with potential for optimization. To change tools on a machine, its work must be interrupted. How long this set-up time lasts is determined not least by the changing system. The more complicated and complex this system is, the higher the demands on the operator responsible and the longer it takes before the machine can be put back into operation. At the same time, every changing system must guarantee maximum safety, reliability, load capacity and efficiency in power transmission, while maintaining a desirable maximum of simplicity in operation.

Consistent progress in process optimization

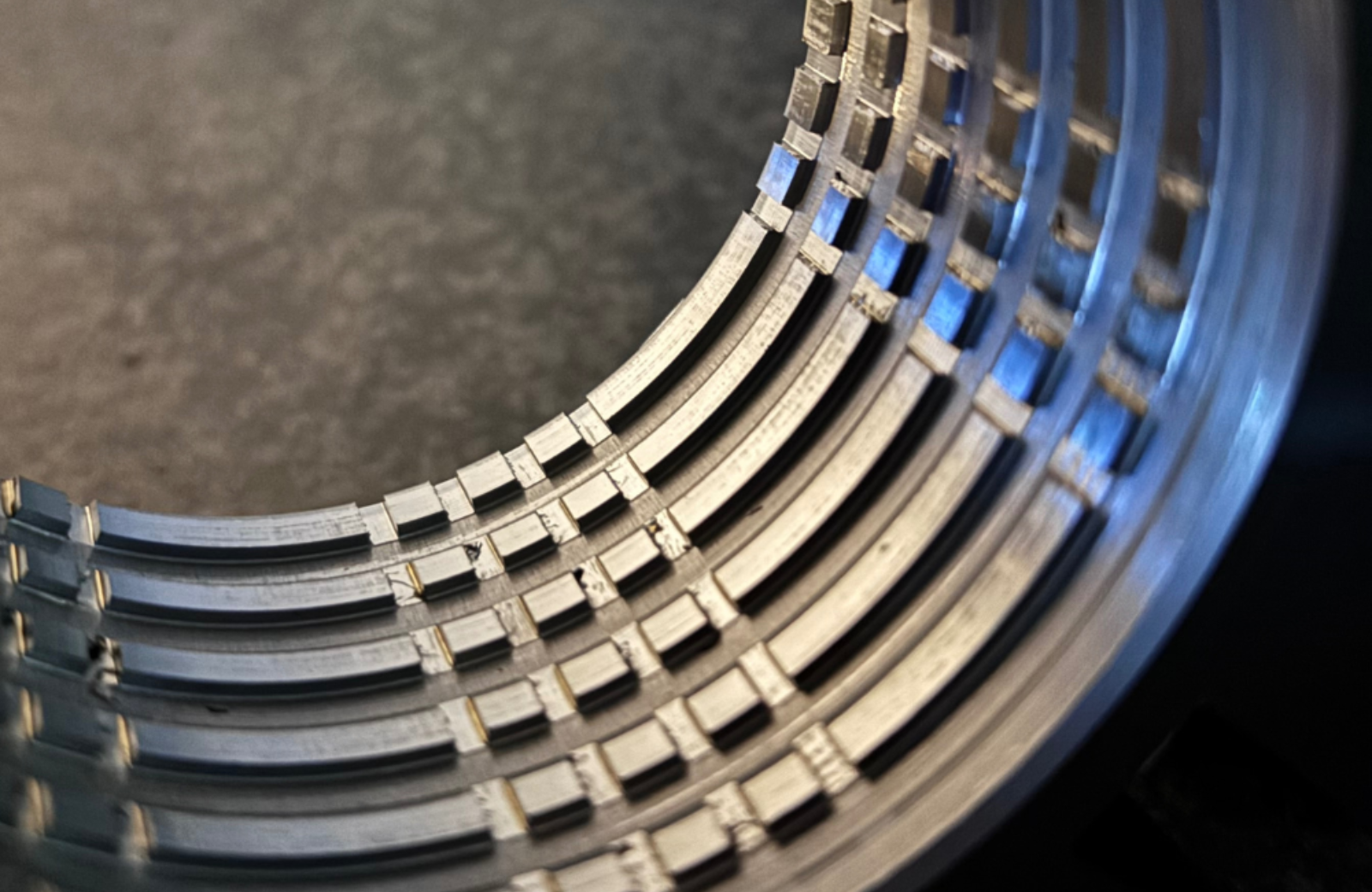

The new EWS.Varia VXT quick-change system meets the requirements for optimizing the tool change process with maximum precision, stability and flexibility. As a solution provider with many years of experience and a driver of innovation in the development, production and distribution of high-precision tool holders for turning and milling machines, tool carrier systems and accessories, EWS has succeeded in further expanding the successful Varia series with the new quick-change system. Designed to meet the requirements of internal turning, the VXT system offers optimum conditions for roughing, finishing, grooving and threading.

When developing the new EWS.Varia VXT, EWS focused not only on performance and efficiency but also on flexibility and cost-effectiveness. The new system is backwards-compatible with EWS.Varia VX. Existing tool holders from the VX system can be upgraded with an EWS.Varia VXT interchangeable insert, making it easy and cost-effective to switch to the new system in stages.

Unrivaled without compromise

The EWS.Varia VXT also impresses with its uncomplicated but reliable handling. The safe and fast one-handed operation, in combination with the use of standard and overhead tools, enables a significant reduction in set-up times for frequent changeover machining. All this is achieved with a compact design compared to other systems. At the same time, users do not have to compromise on stability, performance and precision. For example, the EWS.Varia VXT3, despite its significantly reduced dimensions, impresses with more than double the clamping depth on both sides compared to an EWS.PSC 40 and the resulting stability. No compromises are necessary in terms of torque, precision of position orientation or repeat accuracy. The stability and damping of the double cone flex system with widely spaced support points and dual surface adaptation for reliable torque absorption have been significantly optimized once again.

Overall, with the new EWS.Varia VXT quick-change system, EWS has created an important basis for reducing set-up times, thereby supporting process optimization and automation and making a valuable contribution to maintaining and expanding competitiveness in industrial metalworking.

The most important links at a glance:

EWS Newsletter: The most important news conveniently in your mailbox