Cooperation is becoming increasingly important, especially in the field of digitization. Particularly when it comes to communication between different systems, it is of immense importance to lay the foundation for future product developments through innovation projects. A good example in this context is the sensor technology of tool systems. End users want data to be brought together in one system and to find a standardized data structure. For machine tool control manufacturers, the standardization of sensor interfaces offers the great advantage of being able to provide a wide range of systems and functions in their infrastructure. In order to meet these requirements, the companies EWS and Benz Tooling have decided to jointly develop the Cybercon4 product further in the future and to use it in their tools.

Cooperation on joint digital strategy

Company |

Hüseyin Sivaz (Head of Sales Germany & Global OEM EWS), Martin Schreiber (Managing Director Benz Tooling), Matthias Weigele (Managing Director EWS), Christoph Zeller (Technical Manager Benz Tooling), Niklas Vogt (Global Head of International Sales and Marketing EWS), Michael Kempf (Sales Manager Benz Tooling).

"Mindset toward common standards"

The product created by the cooperation enables customers to read out relevant data and measured values from EWS and Benz Tooling aggregates via an app. "For us it is clear: despite the competitive situation with products from Benz Tooling, we want to act in line with the market in the area of recording, processing and providing tool data and provide our digital services with one language and one technology," says Matthias Weigele, CEO of EWS Weigele GmbH & Co. KG. "If the digital transformation in mechanical engineering is to succeed and individual components are to communicate reliably with the machine control system, the mindset of market players must change towards common standards," adds Martin Schreiber, CEO of Benz Tooling.

This is Cybercon4

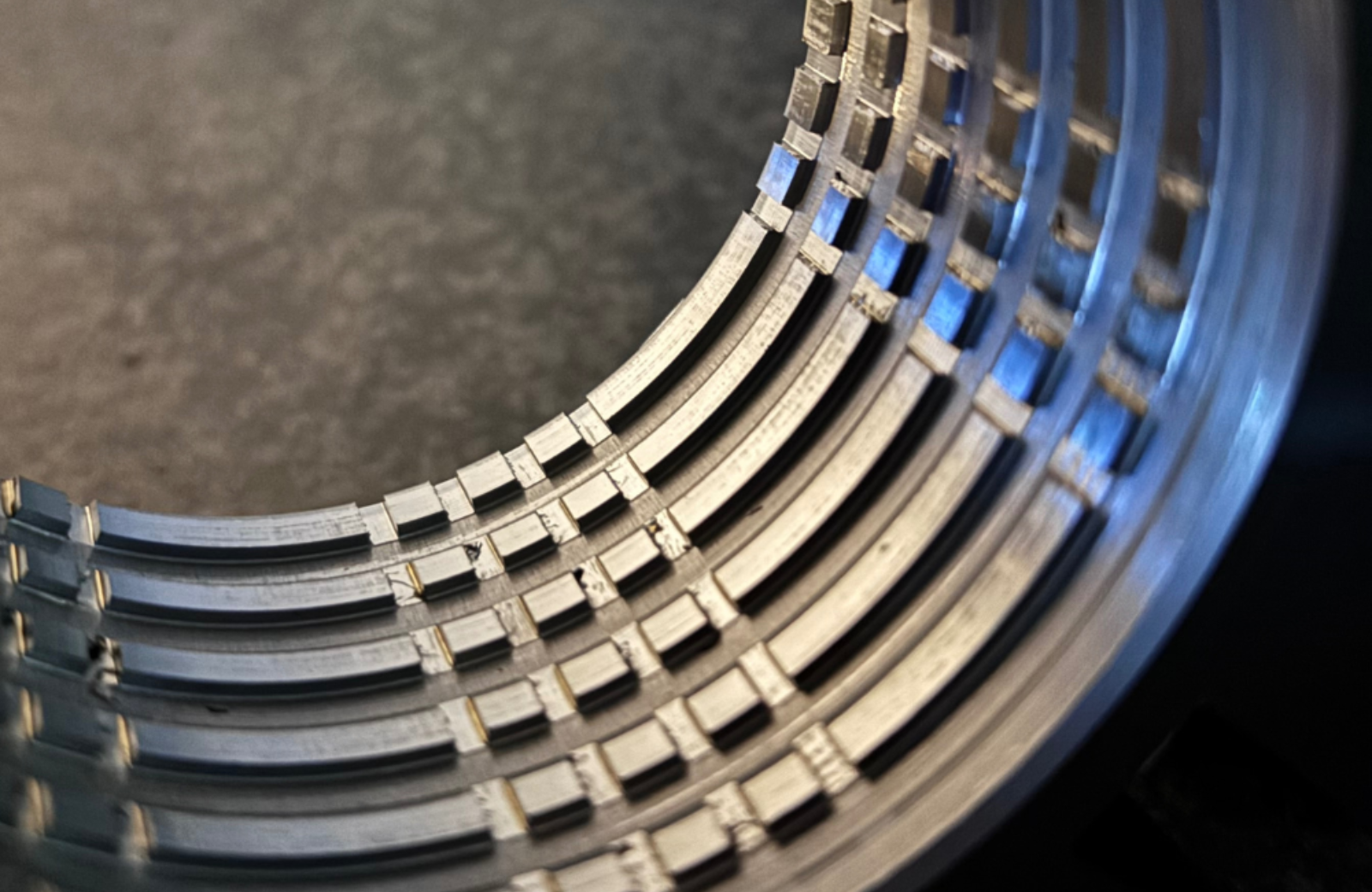

Cybercon4 is a Bluetooth Low Energy sensor technology that can be used to determine and transmit running times, speeds, mold temperatures and maintenance intervals. The developers of the Fluid Control module are particularly proud of the latest innovation, the detection of water ingress into the unit. For the first time, it makes it possible to detect the seal failure of a mold system. Particularly in the case of internally cooled driven tools on lathes, which are operated with a coolant pressure of up to 100 bar, seal failure can lead to costly turret damage. The machine downtime associated with a failure further increases the cost and time pressure. The sensor integrated into the mold is powered by a replaceable battery. Battery replacement is required about once a year in normal industrial use. A property right has been registered for the Cybercon4 technology.

Further expand partnership

EWS and Benz Tooling by no means see their joint development as an individual solution. On the contrary: as this technology becomes more established, both partners expect increasing interest from users and the market as a whole. "We started in this constellation and would like to expand the partnerships further in perspective and connect additional technology users," says Christoph Zeller, technical director of the Haslach-based company. EWS will predominantly integrate the sensor technology with additional functions into its new technology series EWS.Techline. The first tools will be available as early as September 2023. At Benz Tooling, the technology will be available for selected products from the beginning of 2024.